PSA Air Separation Unit for Nitrogen Gas 60Nm3

Model | Capacity (Nm³/h) | Feed Gas | Product gas:nitrogen gas |

Pressure (Mpa) | Dew point (℃) | Residual oil (ppm) | Dew point (℃) | Purity (%) | Pressure (Mpa) | Temperature |

XRFD98 | 5-2000 | 0.7-1.0 | ≤-17 | ≤0.003 | ≤-40 | ≥98 | 0.6-0.9 | Ambient temperature |

XRFD29 | ≥99 |

XRFD295 | ≥99.5 |

XRFD39 | ≥99.9 |

XRFD49 | ≥99.99 |

XRFD59 | ≥99.999 |

Pressure Swing Adsorption is a common air separation method tosepate nitrogen or oxygen from air .The separation process operate around ambient temperature.PSA Air Separation Plant for nitrogen gas takes the carbon molecular sieve as the adsorbent,which adsorbs oxygen and water vapor molecules under high pressure - while allowing Nitrogen to pass through,so that the nitrogen is separated from the air.

Nitrogen offers a wide range of applications such as purging, firefighter, creating inert atmosphere, carrier gas, blanketing, packing, filling, plastic molding, so on and so forth. PSA Air separation plant for nitrogen is on -site nitrogen generation, a favorable choice for many manufacturers as it is an easy and reliable way for them to save money and give free control over the nitrogen gas use,also reliable and cost effective way to get the nitrogen for industrial usage.

Main Technical Indicators:

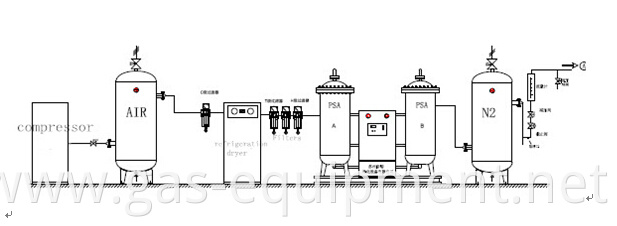

Technological Process

Ambient air, having being compressed and purified to remove oil, water and dust, enters the adsoption swing adsorping device with two adsorption towers filled with carcon molecular sieve(CMS). The compressed air flow to the adsorption tower from the bottom to up. In the process, oxygen molecular is adsorbed, while nitrogen flows out of the upper side of adsorption tower and then enters then buffer tank for impure nitrogen. After a period of time, the CMS in the adsorption tower is saturated by the oxygen adsorbed. At this time, regeneration is needed. It is realized by stopping adsorbing step and reduce pressure in the adsorption tower. Adsorption and regeneration are conducted alternatively in the two adsorption towers to ensure the consecutive output of nitrogen gas.

The whole system components:

The whole nitrogen generation system mainly consists of the air compressor, the compressed air receiver, filters, refrigeration dryer, the PSA nitrogen generator, and the nitrogne receiving tank.

For the air compressor, famous brand such as the Atlas Copco, the Ingersoll Rand can be available from our company to match the PSA Nitrogen generators.

For filters, the elements with brand of Hankison, Domnick are available.

For refrigeration dryer, we have J.mec, the first brand within China, also Hanzhou Union Filter the professional manufacturer of dryer and filters.

Enhancement:To ensure the better quality and longer service life, the main parts such as CMS and PLC, we use world famous brand Japan Takeda and MITSUBISHI, for valves, we use Germany Burkert solenoid valves and pneumatic valves.

FAQ

What is the service life of Carbon molecular sieves(CMS)

Usually, for normally use, the life span of the CMS is about 5 to 8 years.

What is the cycle time to replace the filter element?

Usually, the filter element needs to be replaced for every 6 to 8 months.